0102030405

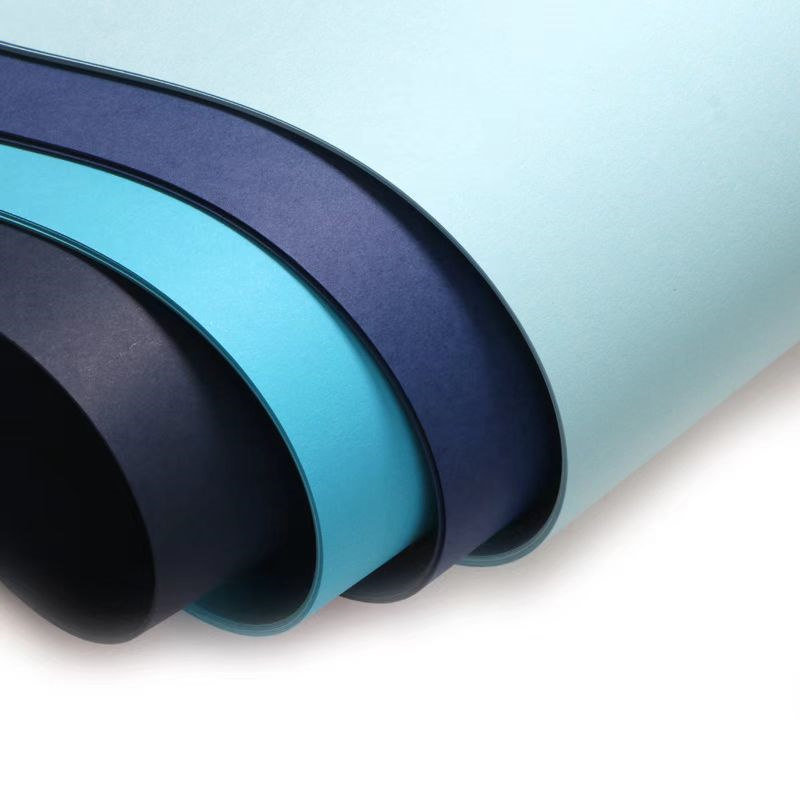

The most cost-effective Direct Fast Blue FBL For Dyeing Paper

Product Specification

|

Name |

Direct Fast Blue FBL |

|

Other Name |

Direct Blue 199 |

|

Cas No. |

12222-04-7 |

|

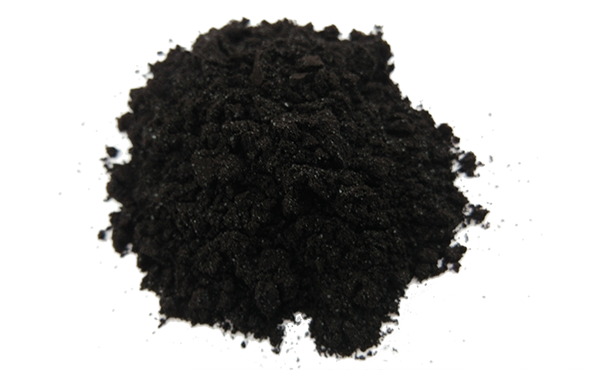

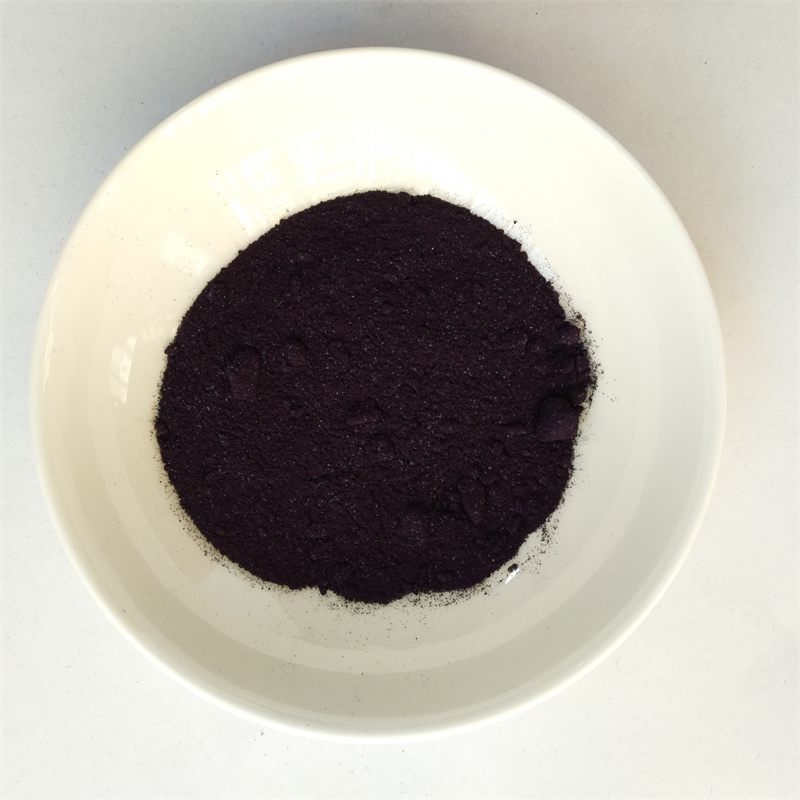

Appearance |

Purple Black Powder |

|

Packing |

25KGS PP Bag/Kraft Bag/Carton Box/Iron Drum |

|

Strength |

100% |

|

Application |

Mainly used for dyeing cotton, viscose fiber, can also be used for leather, silk, paper and so on. |

Product Description

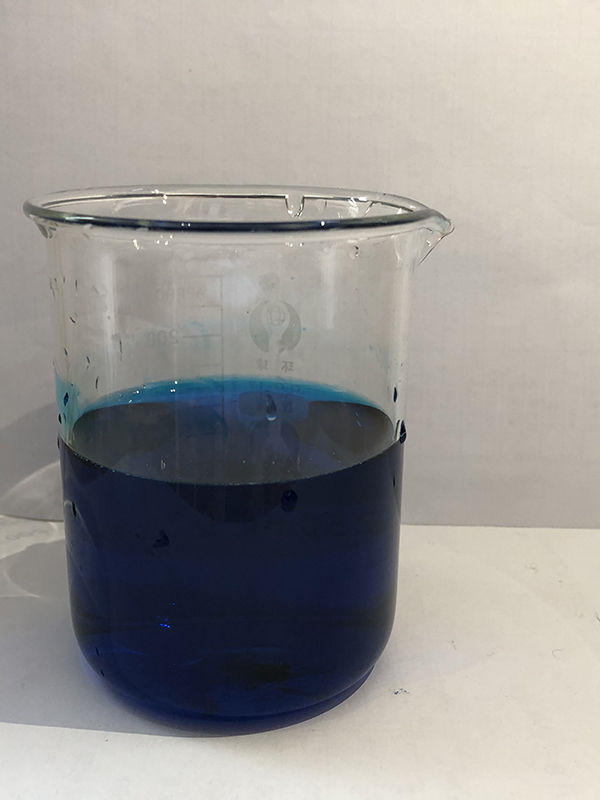

Soluble in water. In concentrated sulfuric acid, it is yellow-green, and after dilution, it is green-blue, with a blue-green precipitate. It is used to dye cellulose fibers, but has poor dye absorption. It reacts to iron ions. We can adjust the Tones and Quality according to the customer's requirements.

Product character

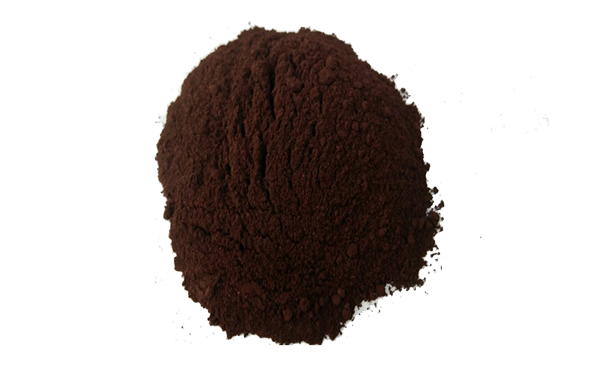

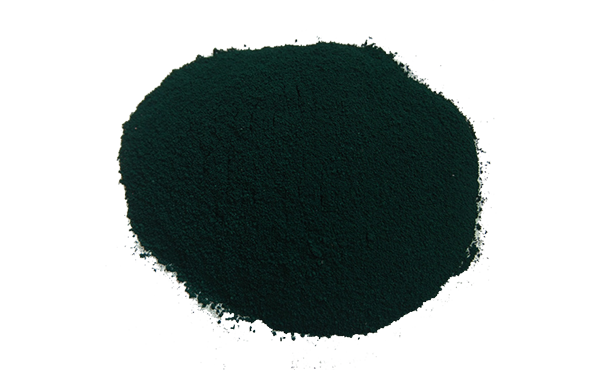

Using copper phthalocyanine as the raw material. Firstly, copper phthalocyanine reacts with chlorosulfonic acid, then sulfonated and chlorosulfated part of it is added with chlorosulfonic acid. After that, it is heated to obtain the product of copper phthalocyanine partially sulfonated and chlorosulfated. Subsequently, sodium bicarbonate, ammonia water and sodium hydroxide aqueous solutions are added successively to complete the neutralization process to obtain the product. After salt precipitation, filtration, drying and grinding, the finished product is obtained. In the reaction bottle, 100g of chlorosulfonic acid is added, heated to 50℃, and copper phthalocyanine 20g is slowly added under stirring. The reaction continues for 1h, then heated to 100℃ and continued for 12h. An appropriate amount of dried sodium chloride can be added for supplementation. When the reaction reaches the end, the reaction liquid is poured into ice water, filtered, washed with ice water. Then the filter cake is placed in ammonia water for pulping, and reacts at 20℃ for 1h. It is heated to 50℃ and maintained for 2h, and an appropriate amount of sodium carbonate is added to maintain pH = 8-9. After the reaction is completed, it is dried at 80℃ under vacuum to obtain the product.

Main features

A.It is used for dyeing cotton and viscose fabrics, and can also be used for dyeing paper. It is one of the important varieties of paper coloring. It can also be used for dyeing silk and leather.

B.It can be combined with Fast Yellow to make Fast Fruit Green. It can also be used for dyeing leather and paper pulp, and for making peacock blue pigment.

C.The dyeing rate is good, but the dyeing transferability is a little worse. After dyeing, it can be treated with fixing agent Y and fixing agent M.

D.It can be ionized into colored anions when dissolved in water. It can be directly dyed on cellulose fibers or protein fibers without the help of mordants. It has a high affinity for cellulose fibers and can be dyed in neutral or weakly alkaline media. When dyeing protein fibers, it is generally done in neutral or weakly acidic media.

Application

It is mostly used for dyeing cotton, viscose fiber, can also be used for leather, silk, paper and so on.

●Dyeing Method

(1)Recipe

|

Dyeing Method |

Weak alkaline |

Medium |

|

Dye.% |

X |

X |

|

Na2CO3.% |

2 |

- |

|

Na2SO4.% |

10-20 |

10-20 |

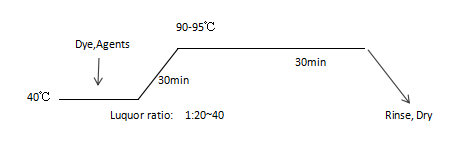

(2)Dyeing Procedure

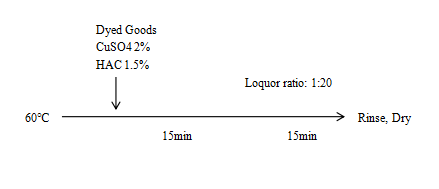

(3)Coppering of copper blue

The product must be stored in shade, dry & well-ventilated warehouse. Avoid to be contacted with oxidizing chemicals and combustible organic substances. Keep it away from direct sunlight, heat, sparks and open flames. Carefully handle the product and avoid damaging the package.

25KGS PP Bag/Kraft Bag/Carton Box/Iron Drum