0102030405

Sulphur Light Green G 7713 300% For Canvas Dyeing

Product Specification

Name |

Sulphur Light Green G 7713 |

Other Names |

Sulphur Green 14 |

CAS No. |

12227-06-4 |

STRENGTH |

300% |

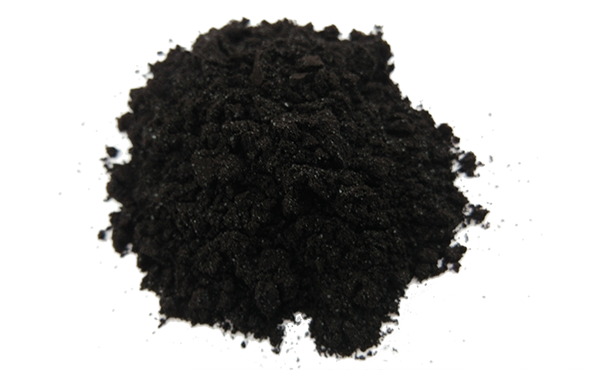

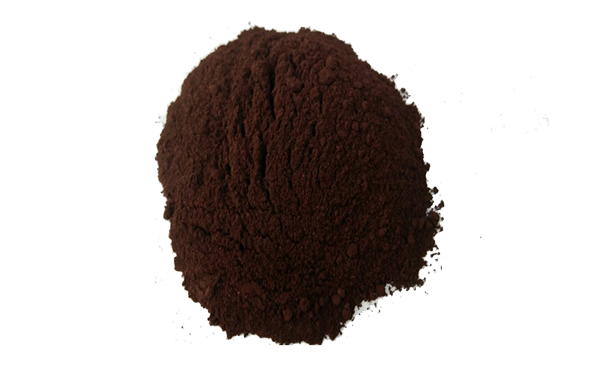

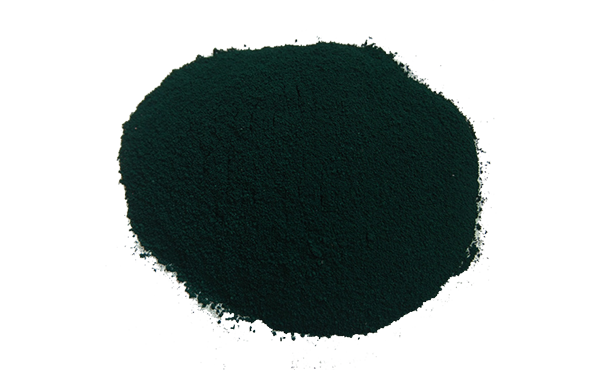

APPEARANCE |

Deep Green Powder |

APPLICATION |

Mainly used for cotton fiber ,cotton blended fabrics dyeing |

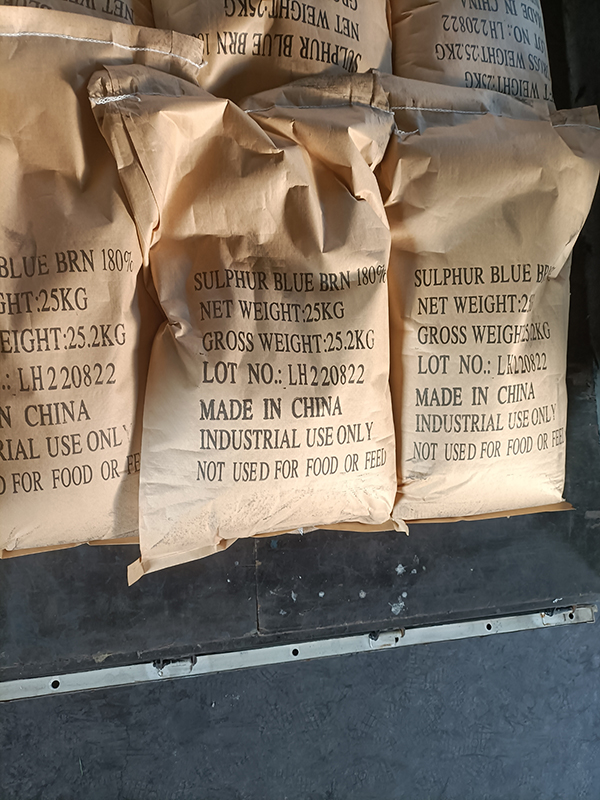

PACKING |

25KGS PP Bag/Kraft Bag/Carton Box/Iron Drum |

Product Description

The Sulphur Light Green G 7713 is our main product. Our company has been committed to providing high service, low miscellaneous, high content products for the field of dyestuff research. Welcome your consultation and purchase.

Product character

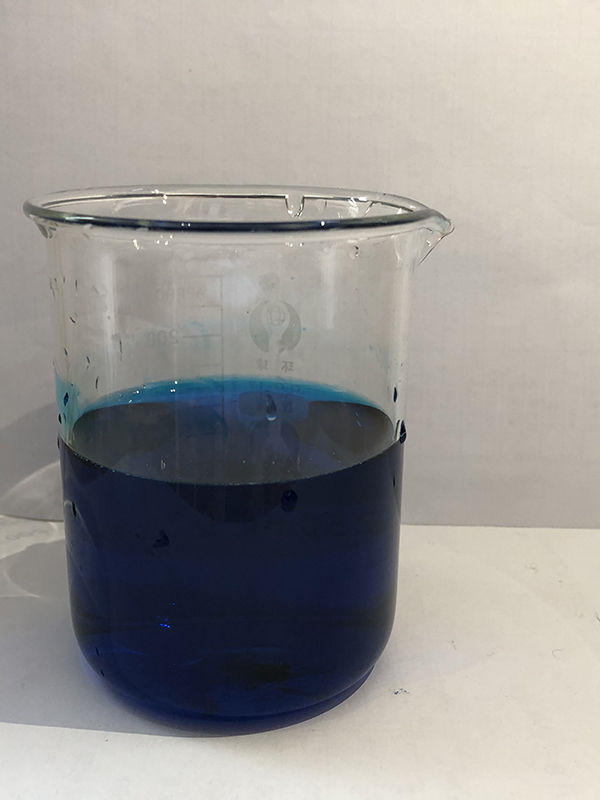

Sulphur Light Green 14 is a dark green powder. It is insoluble in water and is blue-gray in sodium sulfide solution. It is a dark yellow solution in sulfuric acid.

Using phthalocyanine blue as the raw material, phthalocyanine blue is first subjected to chlorosulfonation reaction with chlorosulfonic acid and thionyl chloride, then iron powder and thiourea are added for reduction, and sulfur is added. Finally, the finished product is obtained by filtering, neutralizing, filtering again, drying, and crushing.

Main features

A. Sulphur Light Green 14 has bright color and excellent dyeing fastness. It has good high temperature dyeing performance and good leveling performance. The most suitable pH value of the dye bath is 9.5, and it is not suitable for dyeing with the insurance powder method. It is not suitable for oxidation in the air after dyeing.

B. The color of Sulphur Light Green 14 is close to Vat Green FFB, and its dyeing performance is better than that of vat dyes. It will not produce white core defects and can replace vat dyes within a certain range.

C. Sulphur Light Green 14 is suitable for dyeing various equipment, such as bobbins, warp beams, hanks, sprays, ropes, etc.

D. Sulphur Light Green 14 can be used for dyeing materials that need to be treated with rubber vulcanization, such as canvas for rubber shoes, etc.

Note:

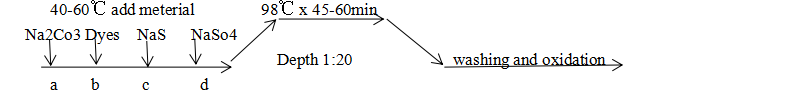

①a--Na2Co(g/L);b--x%(0.w.f);c--Na2S:dyes=2~1:1;d--Na2So4(5-10g/L);

②The dyes is applied in advance to the commendation(wetting);

③After add dyes,usually heat at 1℃/min,heating to 98-100℃,and then keep the temperature 45-60 min for dyeing.

④After dyeing,washing→ Oxidation of air or oxidants,40℃ and keeping 20min →washing→drying

The Sulphur Light Green G 7713 must be stored in shade, dry & well-ventilated warehouse. Avoid to be contacted with oxidizing chemicals and combustible organic substances. Keep it away from direct sunlight, heat, sparks and open flames. Carefully handle the product and avoid damaging the package.

25KGS Kraft Bag/Fibre Drum/Carton Box/Iron Drum