0102030405

Sulphur Dark Blue 3R 100% For Deep Blue Powder

Product Specification

Name |

Sulphur Blue 3R |

Other Names |

Sulphur Blue 5 |

STRENGTH |

100% 130% |

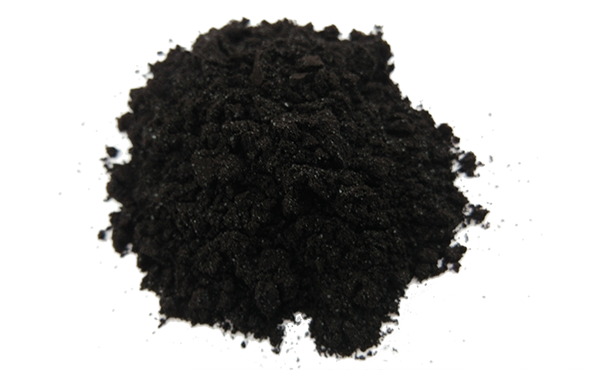

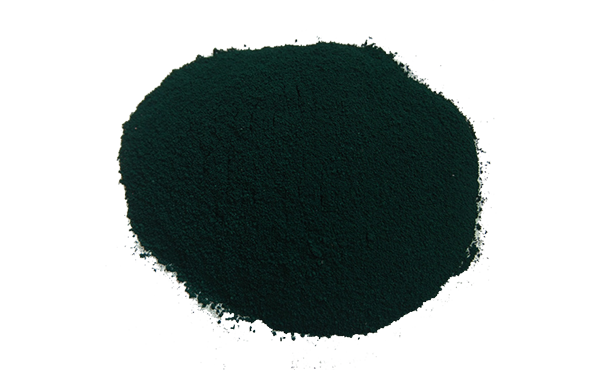

APPEARANCE |

Deep Blue Powder |

APPLICATION |

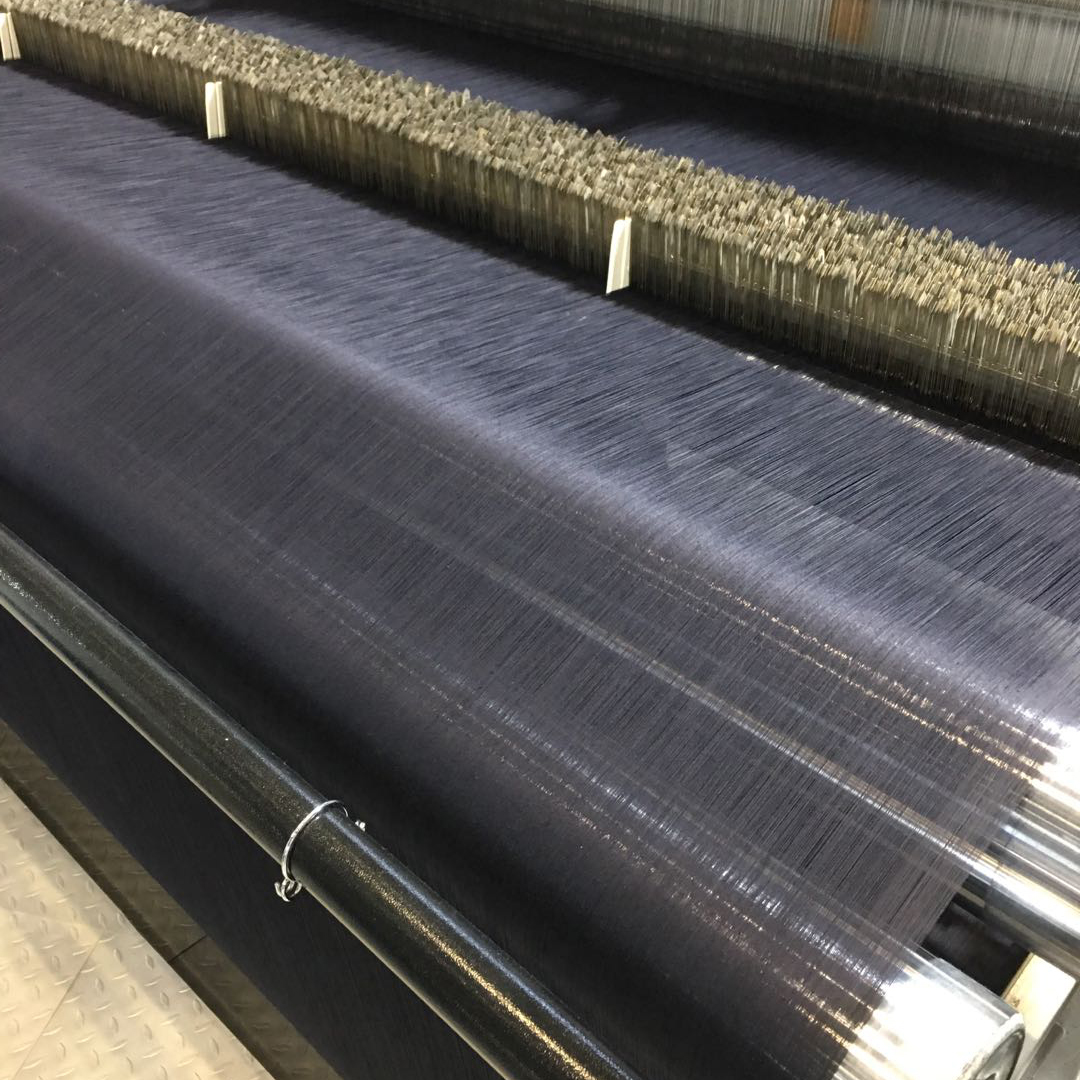

Used for dyeing Cotton, Jeans ,Denim and so on. |

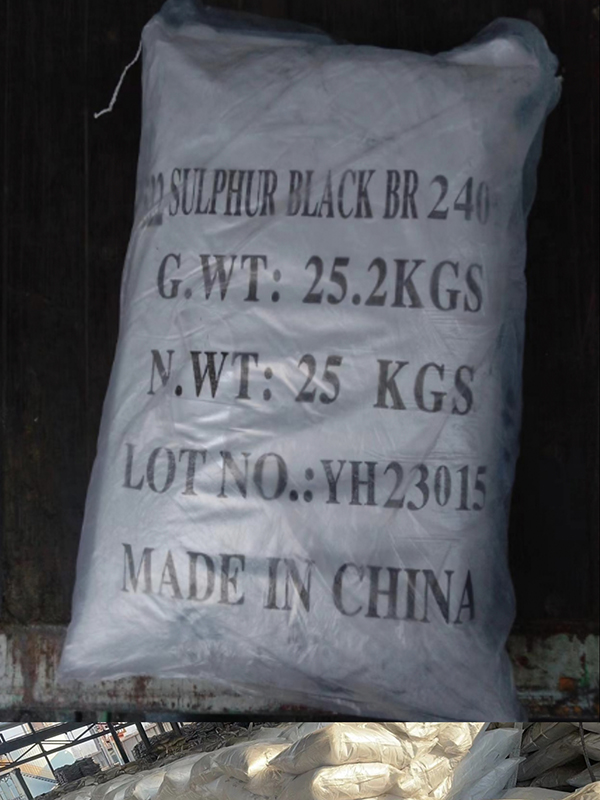

PACKING |

25KGS PP Bag/Kraft Bag/Carton Box/Iron Drum |

Product Description

Sulphur Blue 5 is a synthetic dye commonly used in the textile industry. It is a bright blue color with good lightfastness and washfastness. Sulphur Blue 5 is pH stable and compatible with other dyes and chemicals.

Product character

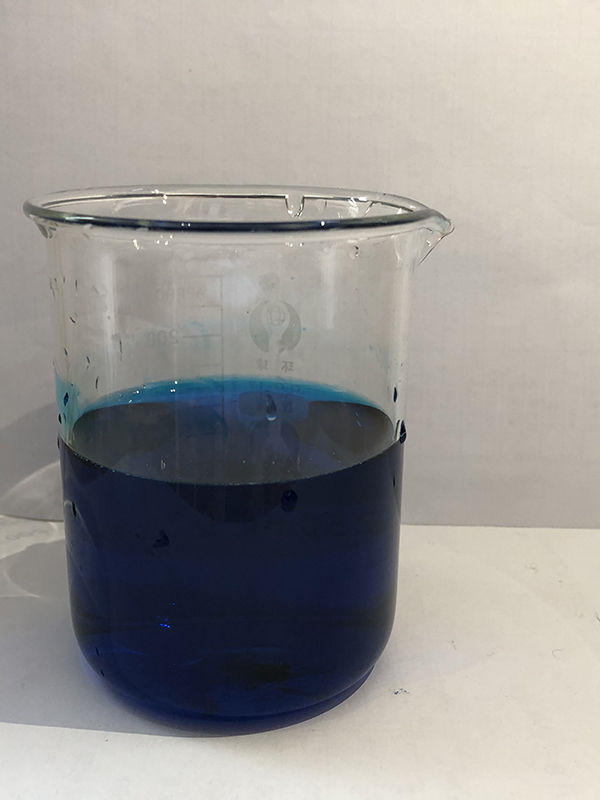

A. Sulphur Blue 5 is a dark blue powder, insoluble in water. Good solubility in sodium sulfide solution, red blue; Blue precipitates after dilution of blue solution in concentrated sulfuric acid.

B. It dissolves in sodium sulfide solution and is greenish-blue. It is blue in concentrated sulfuric acid and produces a dark blue precipitate after dilution. Light olive color in alkaline powder solution. Completely discolored in sodium hypochlorite solution.

C. Sulphur Blue 5 is compatible with a wide range of other dyes and chemicals used in textile dyeing, including reducing agents, alkalis, and salts.

Main features

Sulphur Blue 5 is a synthetic dye that is commonly used in the textile industry. Its main features include:

Color: Sulphur Blue 5 is a bright blue color with a strong tinting strength. It is commonly used to dye cotton,Denim and other natural fibers.

Chemical composition: Sulphur Blue 5 is a sulfide dye, which means it contains sulfur atoms in its chemical structure. Its molecular formula is C34H22N6Na2O10S6.

Lightfastness: Sulphur Blue 5 has good lightfastness, meaning it is resistant to fading when exposed to light. This makes it suitable for use in textiles that will be exposed to sunlight, such as outdoor fabrics.

Washfastness: Sulphur Blue 5 has good washfastness, meaning it does not easily wash out of fabrics when they are laundered. This makes it suitable for use in clothing and other textiles that will be washed frequently.

Note:

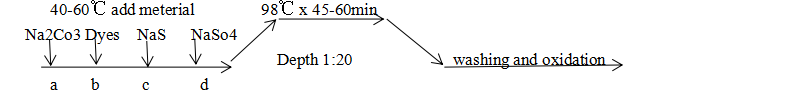

①a--Na2Co(g/L);b--x%(0.w.f);c--Na2S:dyes=2~1:1;d--Na2So4(5-10g/L);

②The dyes is applied in advance to the commendation(wetting);

③After add dyes,usually heat at 1℃/min,heating to 98-100℃,and then keep the temperature 45-60 min for dyeing.

④After dyeing,washing→ Oxidation of air or oxidants,40℃ and keeping 20min →washing→drying

The product must be stored in shade, dry & well-ventilated warehouse. Avoid to be contacted with oxidizing chemicals and combustible organic substances. Keep it away from direct sunlight, heat, sparks and open flames. Carefully handle the product and avoid damaging the package.

25KGS Kraft Bag/Fibre Drum/Carton Box/Iron Drum