010203

Sulphur Blue BRN 150% For Bluish Violet Powder

Product Specification

Name |

Sulphur Blue BRN |

Other Names |

Sulphur Blue 7 |

CAS No. |

1327-57-7 |

STRENGTH |

120%-180% |

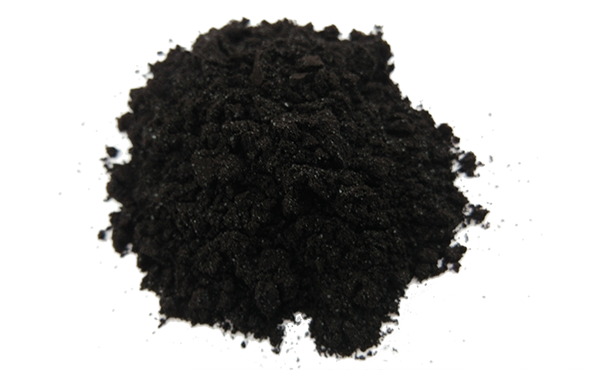

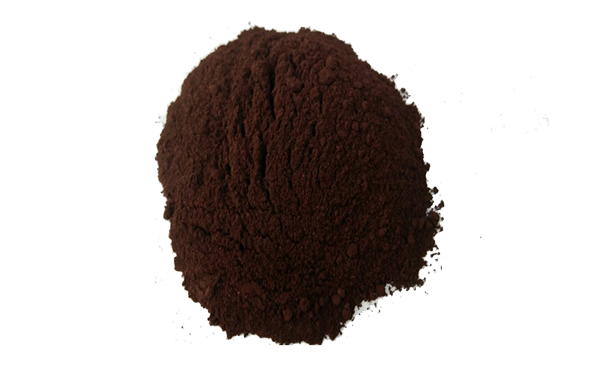

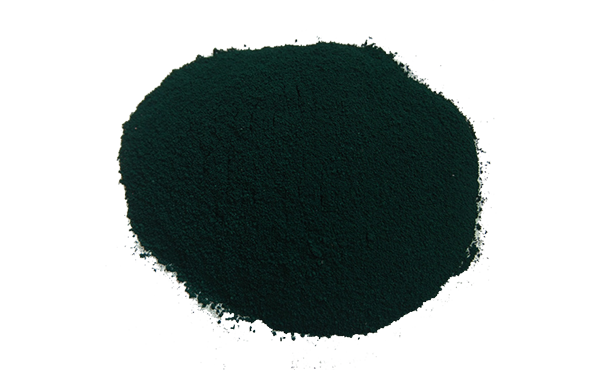

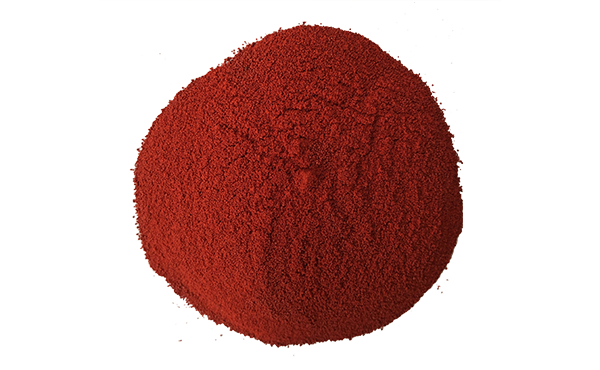

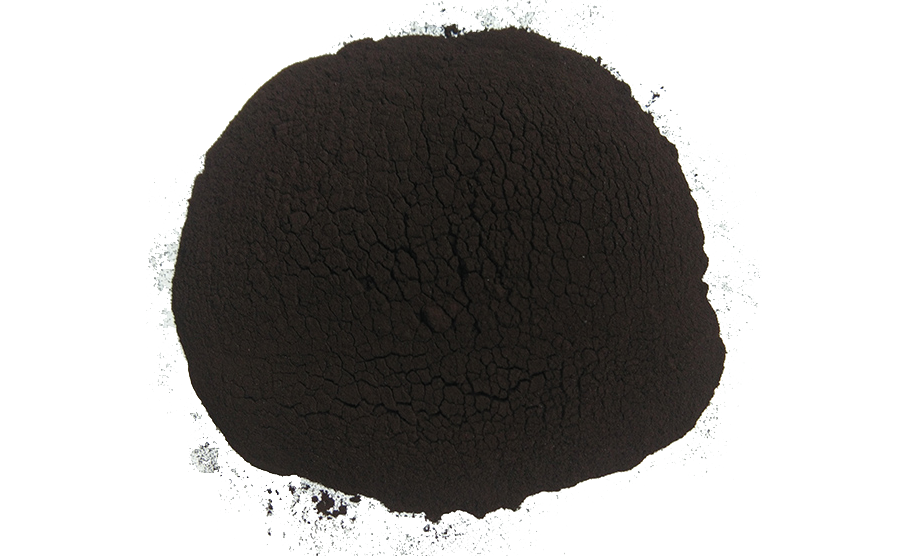

APPEARANCE |

Bluish Violet Powder |

APPLICATION |

Used for dyeing Cotton, Jeans ,Denim and so on. |

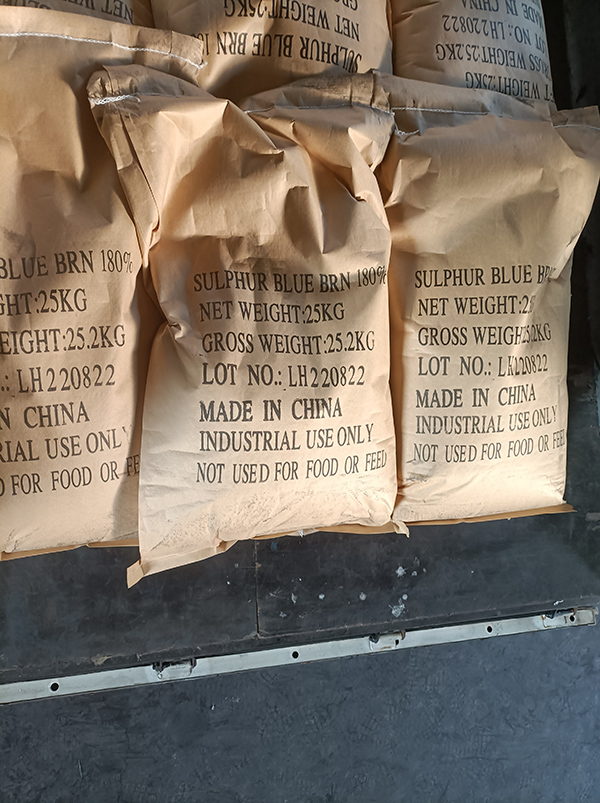

PACKING |

25KGS PP Bag/Kraft Bag/Carton Box/Iron Drum |

Product Description

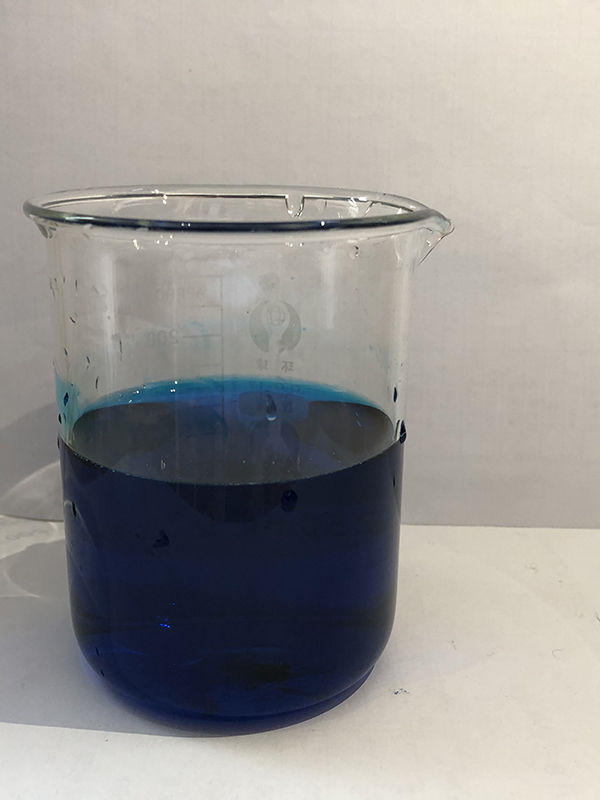

Sulphur Blue can be classified as BRN (Reddish) and BN(Bluish)by their different tones, and the tone and quality can be adjusted according to the customer's requirements. In the water have certain solubility. In concentrated sulfuric acid to dark purple, and Sulfur dioxide escaping, dilute precipitate; In the Sodium hydroxide solution for blue; In the Sodium sulfide solution for the faint blue or olive. Dyeing content in alkaline insurance powder solution for the pale yellow light olive, after oxidation can restore the original colour and lustre; In Sodium hypochlorite solution completely fade.

Product character

A.Strength:120%- 180%

B.Standard greenish and reddish tone

C.Can be dissolved directly in water without adding any sodium sulfide.

D. Sulphur blue dye powder are uniform and the strength is uniform,and it is

not easy to cause color color in dyeing. In addition,the level of environmental pollution is less.

E.The Sulphur blue dye has better wetting,fluidity,solubility,superior application

performance,dyeing is not easy to cause color spots,flower cloth,color difference,

and the degree of each degree is better than generally.

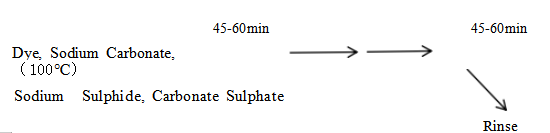

First, Microtherm Dyeing

1. Dyeing procedure:

2. (Dyeing is started advantageously at 60℃)

3. illustrate

① Dyeing is started advantageously at 60 ℃ , In the case of dyes which are to be dyed hot, the temperature is raised to the boil slowly and the material dyed near the boil for 45-60 minutes.

②Dyes could be carried out at the temperature above 80 ℃ for 45-60 minutes by the initial temperature at 50-55℃ .

③With dyes which yield brighter and in particular fuller dyeing at low temparature,the goods are entered to the dyebath at30-40C , and dyed at50-60℃for 45minutes.Also when pale shades are needed,the goods are entered at low temperatureand the bath should be heated gradully.In this case,dyeing is carried out best without addition of sodium sulphate.

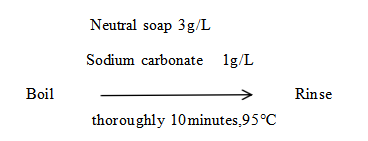

Second, Aftertrentment

After dyeing, hydroextrated or Squeezed off carefully > Rinse thoroughly

Oxidized by airing or Oxidized (With three methods) > Rinse and soaping

The product must be stored in shade, dry & well-ventilated warehouse. Avoid to be contacted with oxidizing chemicals and combustible organic substances. Keep it away from direct sunlight, heat, sparks and open flames. Carefully handle the product and avoid damaging the package.

25KGS Kraft Bag/Fibre Drum/Carton Box/Iron Drum