01

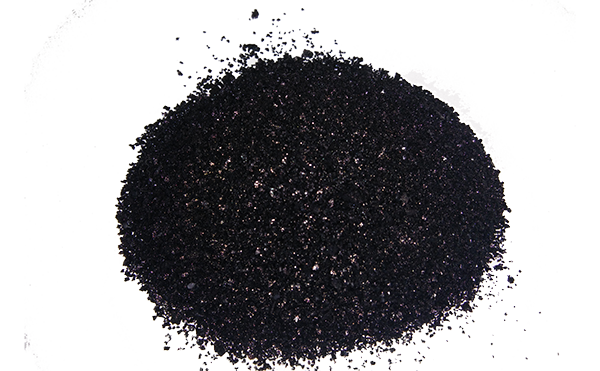

Sulphur Black BR With Shinning Granule For Denim

Product Specification

Name |

Sulphur Black BR |

Other Names |

Sulphur Black 1 |

CAS No. |

1326-82-5 |

EINECS No.: |

215-444-2 |

STRENGTH |

300% 240% 220%200%190% 180% 170% 150% and so on. |

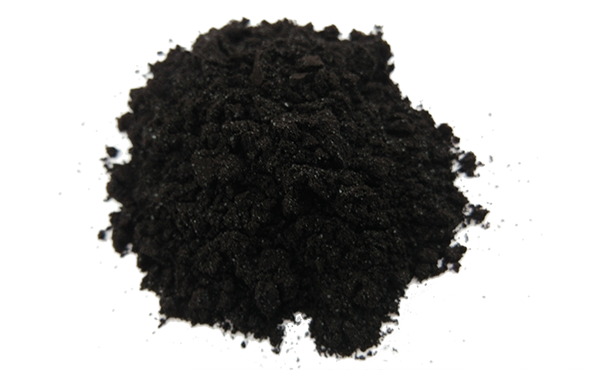

APPEARANCE |

Big Shining Black Flakes or Granules |

APPLICATION |

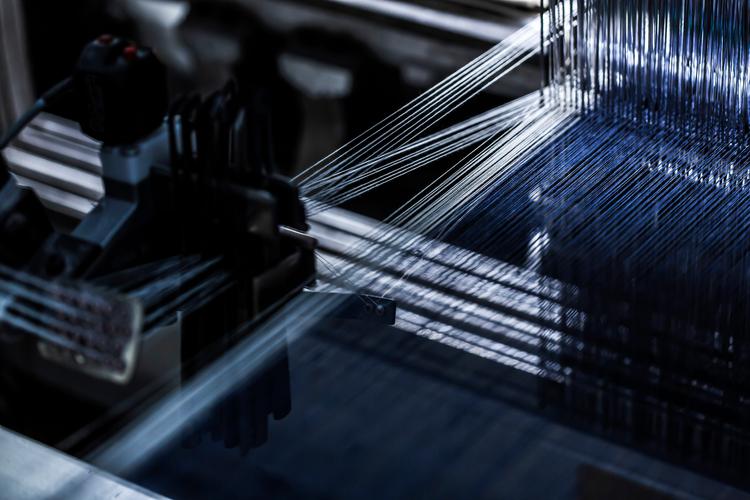

Used for dyeing Cotton, Jeans ,Denim and so on. |

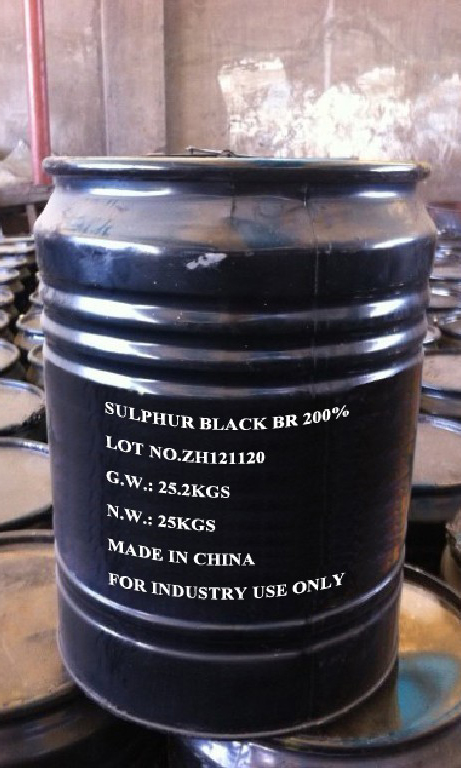

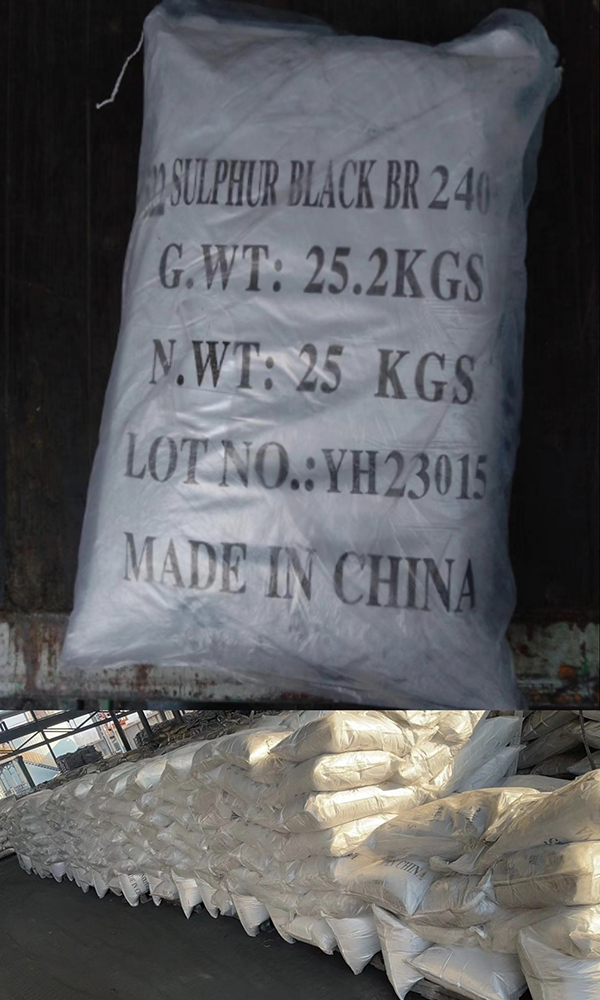

PACKING |

25KGS PP Bag/Kraft Bag/Iron Drum |

Product Description

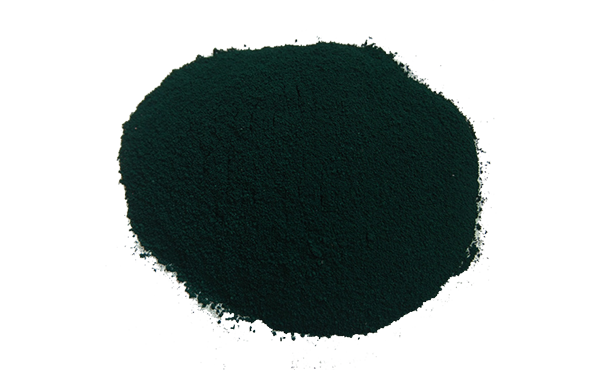

We can provide 2 color shades:BR 522 (Reddish Tone) and B 521 (Greenish Tone),and we can adjust the Tones and Quality according to the customer's requirements.

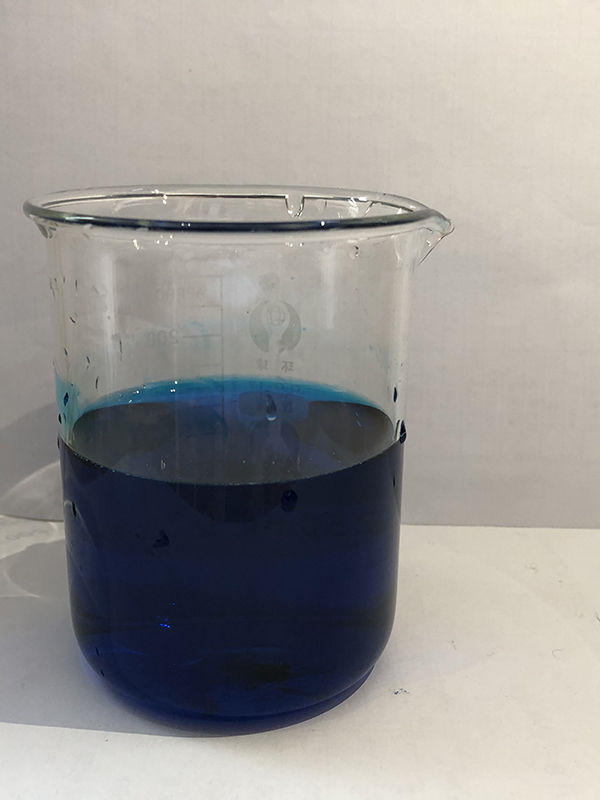

1.Sulphur Black is Shining and Black Flakes or Granules. Insoluble in water and alcohol, soluble in sodium sulfide solution and it turns green-black. Adding sodium hydroxide into sulphur black solution, the color is bluish. Adding hydrochloric acid into sulphur black solution, it becomes a greenish black precipitate.

2.Slightly soluble in cold concentrated sulfuric acid. It is dark green light blue in hot concentrated sulfuric acid, and turns into dark blue when heated continuously.

3.The dyed matter is yellow and lemon-colored in alkaline sodium hydrosulfite solution, and can restore its original color after oxidation; it will completely fade in sodium hypochlorite solution; it will not be affected by concentrated sulfuric acid.

Product character

1.Sulphur dyes have good dye-uptake and level dyeing.

2.Especially suitable for dyeing cotton, linen, viscose, vinylon and other thick fabrics dark color spectrum, simple process, easy to use, need to add antioxidants when dyeing light colors, no antioxidants when dyeing dark colors, stable color, bright color, high wetness fastness, small color difference, can improve the qualified rate of finished products.

3.The dye has a high dyeing rate on the fiber and good uniformity; However, the rate of oxidation is slower. After dyeing, the water should be washed sufficiently, so that the sulfide alkali remaining on the cloth surface is removed, the dye oxidation is accelerated, and the cloth surface is uniform. The temperature is below 70 °C, the color is dark and vivid, the temperature is too high, the color light turns gray, and the uniformity is poor.

4.Sulphur black has high light resistance and weather resistance, and is not susceptible to fading by light and oxygen.

5.Sulphur Black can be used for dyeing cotton, hemp, viscose and other fibers, its manufacturing process is simple, low cost, can be dyed monochrome, but also can be mixed color, good fastness to sunlight, poor fastness to wear.

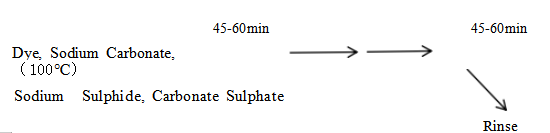

First, Microtherm Dyeing

1. Dyeing procedure:

2. (Dyeing is started advantageously at 60℃)

3. illustrate

① Dyeing is started advantageously at 60 ℃ , In the case of dyes which are to be dyed hot, the temperature is raised to the boil slowly and the material dyed near the boil for 45-60 minutes.

②Dyes could be carried out at the temperature above 80 ℃ for 45-60 minutes by the initial temperature at 50-55℃ .

③With dyes which yield brighter and in particular fuller dyeing at low temparature,the goods are entered to the dyebath at30-40C , and dyed at50-60℃for 45minutes.Also when pale shades are

needed,the goods are entered at low temperatureand the bath should be heated gradully.In this case,dyeing is carried out best without addition of sodium sulphate.

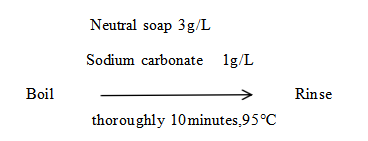

Second, Aftertrentment

After dyeing, hydroextrated or Squeezed off carefully Rinse thoroughly

Oxidized by airing or Oxidized (With three methods) Rinse and soaping

The Sulphur Black BR must be stored in shade, dry & well-ventilated warehouse. Avoid to be contacted with oxidizing chemicals and combustible organic substances. Keep it away from direct sunlight, heat, sparks and open flames. Carefully handle the product and avoid damaging the package.

25KGS Kraft Bag/PP Bag/Iron Drum