0102030405

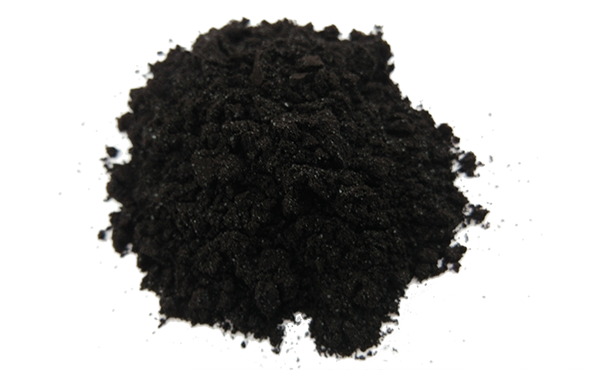

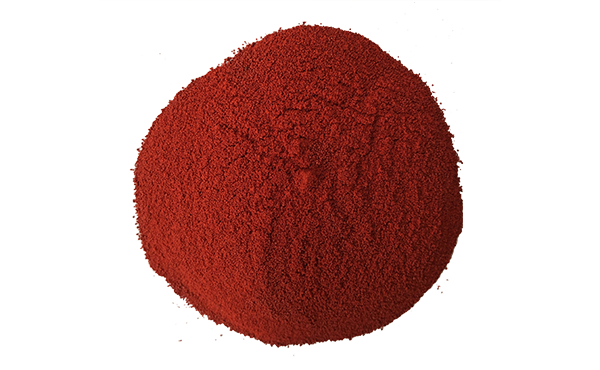

Reactive Blue 21 100% with blue powder

Product Specification

|

Name |

Reactive Blue 21 |

|

Other Names |

|

|

CAS No. |

12236-86-1 |

|

STRENGTH |

100% |

|

APPEARANCE |

Blue Powder |

|

APPLICATION |

Used for dyeing silk, wool, leather, paper, hemp and so on. |

|

PACKING |

25KGS PP Bags/Kraft Bag/Carton Box/Carton Drum |

Product Description

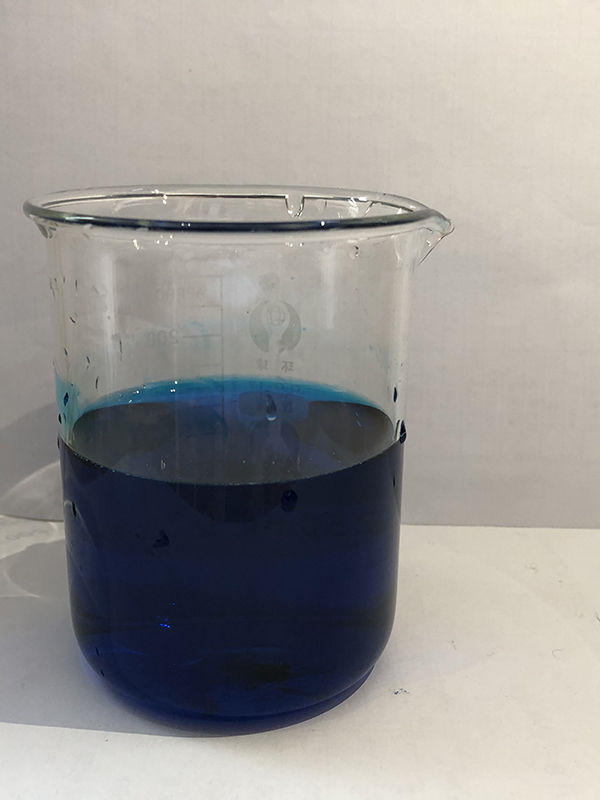

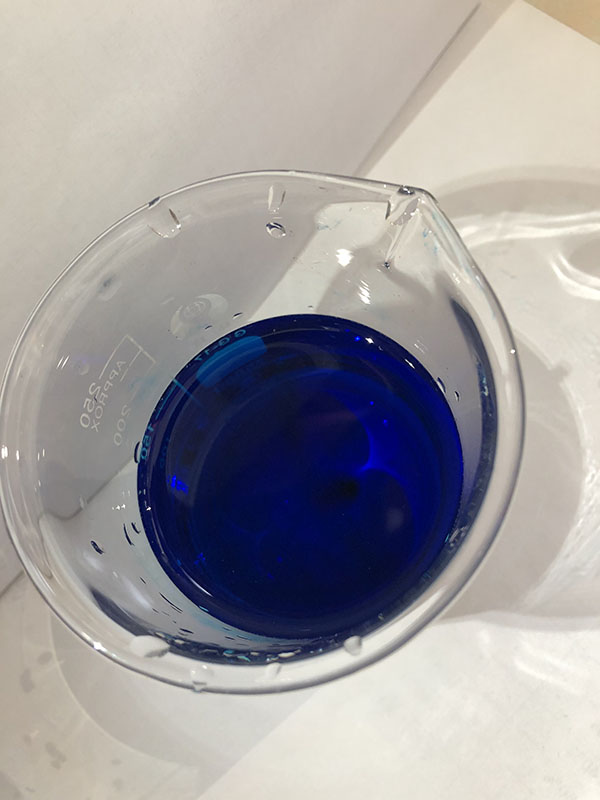

Reactive Blue 21 (Reactive Turquoise Blue Kn-G),Blue powder. Solubility in water (20℃) is 100g/L. The aqueous solution is lake blue. The color does not change when 1mol/L sodium hydroxide is added. It turns purple when hydrosulfite is added and warmed. Then sodium perborate is added to restore the original color, which is slightly lighter. It turns blue in concentrated sulfuric acid and does not change after dilution. It turns green in concentrated nitric acid and the color is slightly lighter after dilution.

Product character

A.Reactive turquoise blue KN-G is rarely used for single color, but is often used for dyeing green, black, green and other colors.

B.Using copper phthalocyanine, p-(2-sulfate ethyl sulfonyl)aniline, chlorosulfonic acid and thionyl chloride as raw materials, firstly, copper phthalocyanine is subjected to chlorosulfonation reaction with chlorosulfonic acid and thionyl chloride, then the product is condensed with p-(2-sulfate ethyl sulfonyl)aniline, and the finished product is obtained through salting out, filtering and drying.

C.It can be used for dyeing cotton and viscose fibers, suitable for various dyeing methods, with medium affinity and low color fixation rate. It can be used for dyeing single colors, and can also be used for green and dark green. It is also used for direct and resist printing of cotton and viscose fiber fabrics, but can only be used for light colors. It is used for dyeing silk, wool, nylon, and vinylon, but has poor light fastness. It is used for direct printing of vinyl-cotton blended fabrics, and can print medium and dark colors with good fastness.

Used for dyeing silk, wool, leather, paper, hemp and so on.

Cold-Pad-Batch Process:

Padding→25℃ Batching 8-12hrs→Washing Off

Pad-Dry-Pad-Steam Process:

Padding Dye Liquor→IR Predrying→Hot air 100-130℃→Padding Chemicals→Saturated steam 45~90sec.→Washing Off

Pad-Dry-Thermofix Process:

Padding.PU50-60%→Drying 110-130℃→Thermofix 140℃ 60sec→Washing Off

The product must be stored in shade, dry & well-ventilated warehouse. Avoid to be contacted with oxidizing chemicals and combustible organic substances. Keep it away from direct sunlight, heat, sparks and open flames. Carefully handle the product and avoid damaging the package.

25KGS PP Bags/Kraft Bag/Carton Box/Iron Drum