0102030405

Direct Scarlet 4BS 100% for dyeing paper

Product Specification

|

Name |

Direct Scarlet 4BS |

|

Other Name |

Direct Red 23 |

|

Cas No. |

3441-14-3 |

|

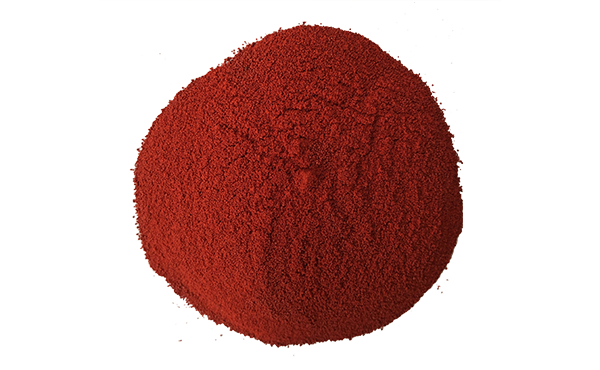

Appearance |

Purple-red powder |

|

Packing |

25kgs Kraft bag/carton box/Iron drum |

|

Strength |

100%,CONC 150% |

|

Application |

Used for dyeing cotton,paper,leather,silk and wool so on.

|

Description

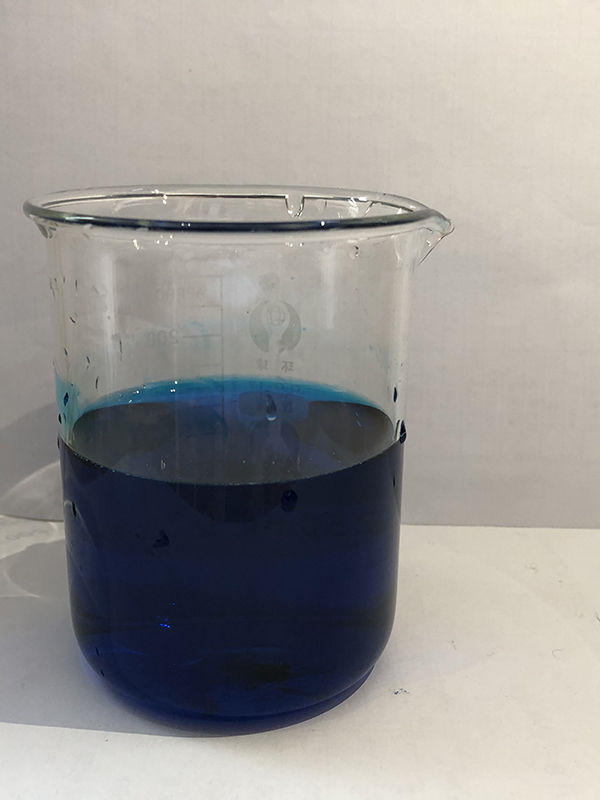

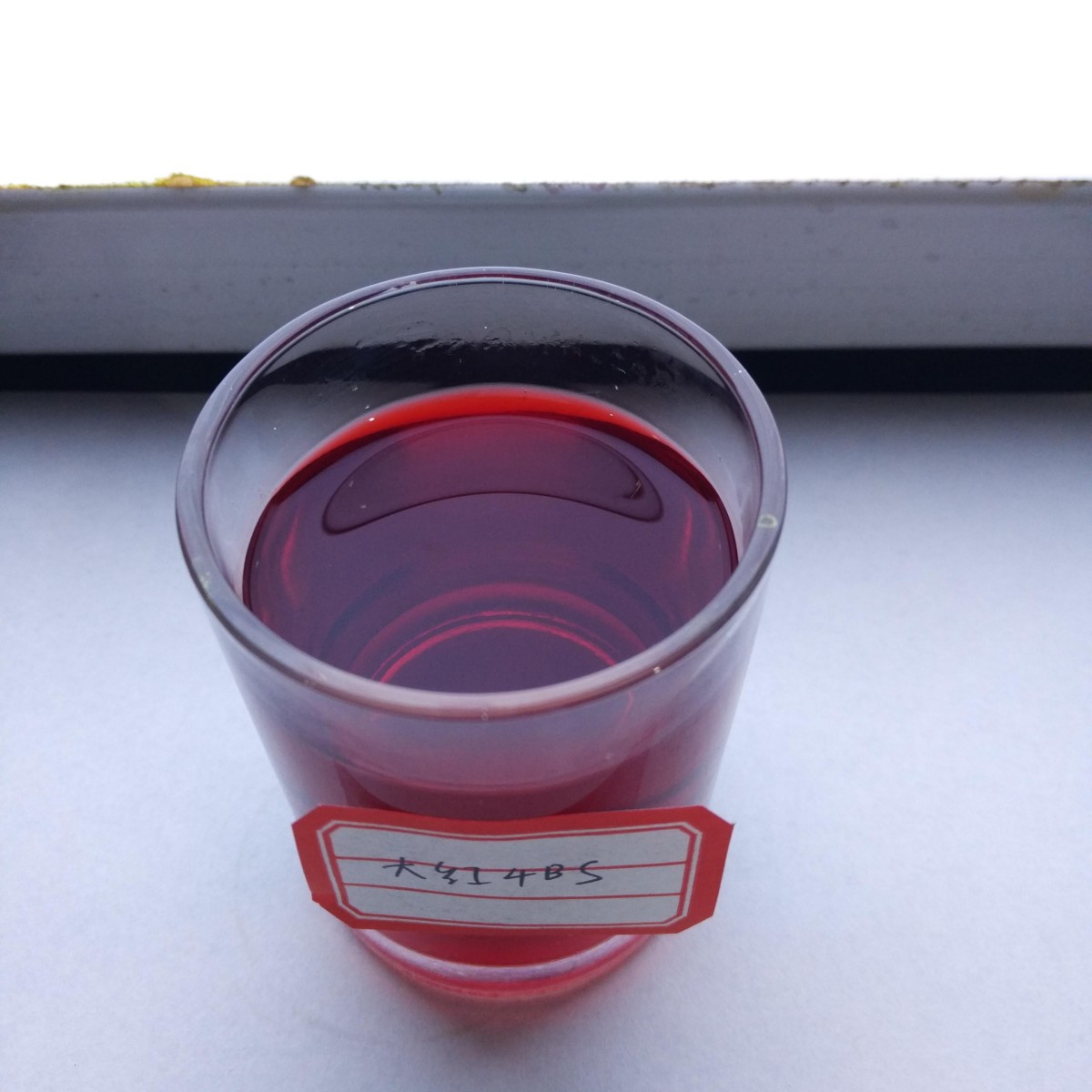

Direct Scarlet 4BS is a Purple-red powder. Soluble in water, It is bright red in water, orange in alcohol, insoluble in acetone.Mostly used for dyeing paper.Dyeing time slowly heating up and add salt to control the dyeing, can get even color. The dyeing bath should be cooled to 80℃ naturally in the late dyeing period to facilitate dye absorption. We can adjust the Tones and Quality according to the customer’s requirements.

Product character

It is bright red to magenta in concentrated sulfuric acid, and turns to brown-orange after dilution; it has an orange-yellow precipitate in concentrated nitric acid; it is insoluble in concentrated caustic soda solution; it is bright red in concentrated ammonia water. Its aqueous solution has a wine-red precipitate when adding concentrated hydrochloric acid; it turns slightly blue when adding 10% sulfuric acid; it turns red-orange-brown when adding concentrated alkali solution; it does not change when adding 10% pure arsenic. It becomes darker when encountering copper light; it is almost unchanged when encountering iron light, and it has good acid resistance.

Main features

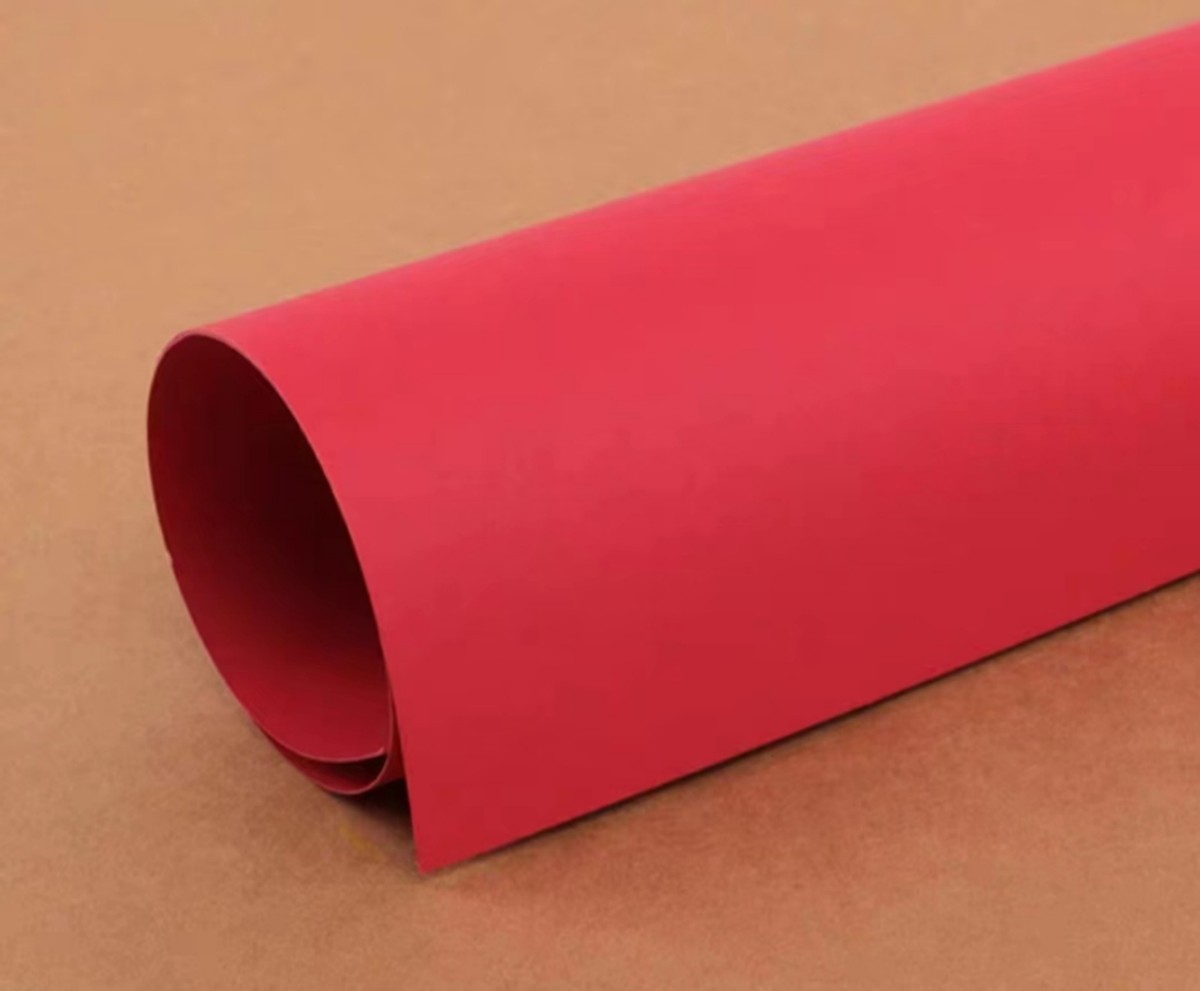

A. It is mainly used for dyeing and printing of fiber fabrics such as cotton, viscose, and linen. It can also be used for dyeing silk and wool, as well as for dyeing paper and leather, and for making lake pigments.

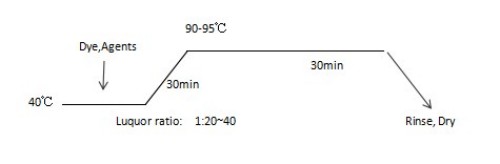

B. It has good dye absorption for dyeing cellulose fibers, and its affinity is the highest at 80-100℃.

C. In addition to being used alone to dye scarlet and madder red (yellow light red), it is also used to combine with yellow, orange, red, brown and other dyes. After dyeing, it is treated with urea-formaldehyde resin or fixing agent Y, and the color remains basically unchanged. If it is treated with fixing agent M, the color becomes obviously blue.

D.The dyeing bath should be cooled to 80℃ naturally in the late dyeing period to facilitate dye absorption.After dyeing, it should be treated with fixing agent to improve wet fastness.

E. Its evenness and transference is poor, dyeing time to add salt to control the dye, in order to get even color.

Application

It is mostly used for dyeing paper,It can also be used for dyeing rayon silk and wool so on.

1)Recipe

|

Dyeing Method |

Weak alkaline |

Medium |

|

Dye.% |

X |

X |

|

Na2CO3.% |

2 |

- |

|

Na2SO4.% |

10-20 |

10-20 |

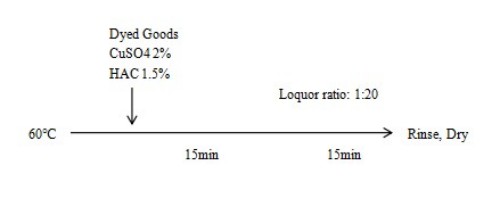

(2)Dyeing Procedure

(3)Coppering of copper blue

The product must be stored in shade, dry & well-ventilated warehouse. Avoid to be contacted with oxidizing chemicals and combustible organic substances. Keep it away from direct sunlight, heat, sparks and open flames. Carefully handle the product and avoid damaging the package.

25kgs Kraft bag/carton box/Iron drum25kgs carton box